2018 High quality Door Frame Rolling Shutter Roll Forming Machine

As for aggressive selling prices, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such high-quality at such price ranges we’ve been the lowest around for 2018 High quality Door Frame Rolling Shutter Roll Forming Machine, Welcome all clients of dwelling and abroad to go to our corporation, to forge a fantastic long term by our cooperation.

As for aggressive selling prices, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such high-quality at such price ranges we’ve been the lowest around for Aluminum Shutter Slat Forming Machine, Door Frame Rolling Shutter Roll Forming Machine, Steel Door Frame Roll Forming Machine, Although continuous opportunity, we now have now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

Description:

The Door Frame Roll Forming Machine include Roman Column Door frame Roll Forming Machine, Lace Door Frame Roll Forming Machine, Curved Door Frame Roll Forming Machine, Straight Door Frame Roll Forming Machine, Door Plank Roll Forming Machine etc. We offer any kinds of door frame roll forming machines according to your profile drawing.

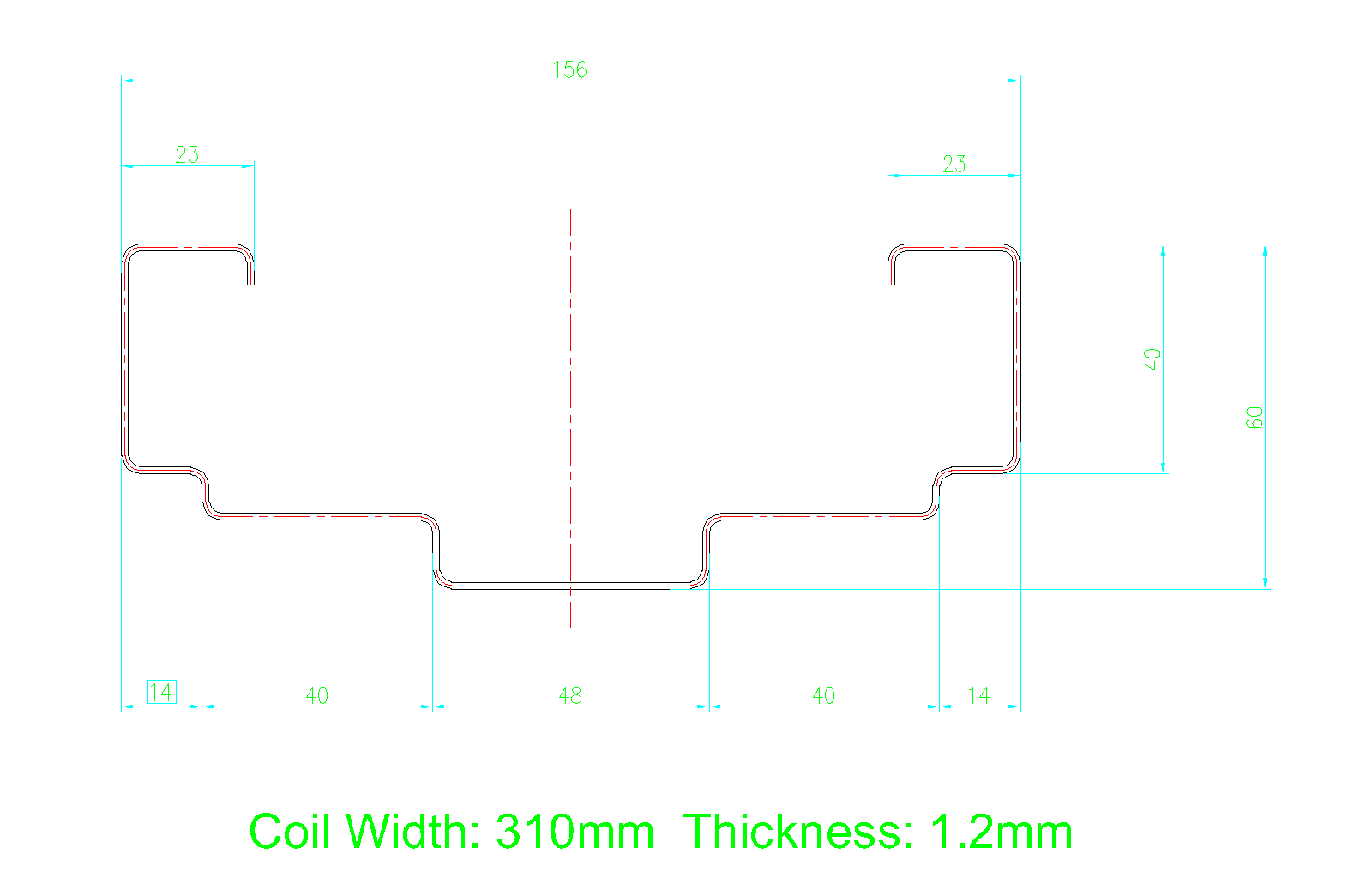

Profile:

Technical specification:

|

Door Frame roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.0-2.0 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

17 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

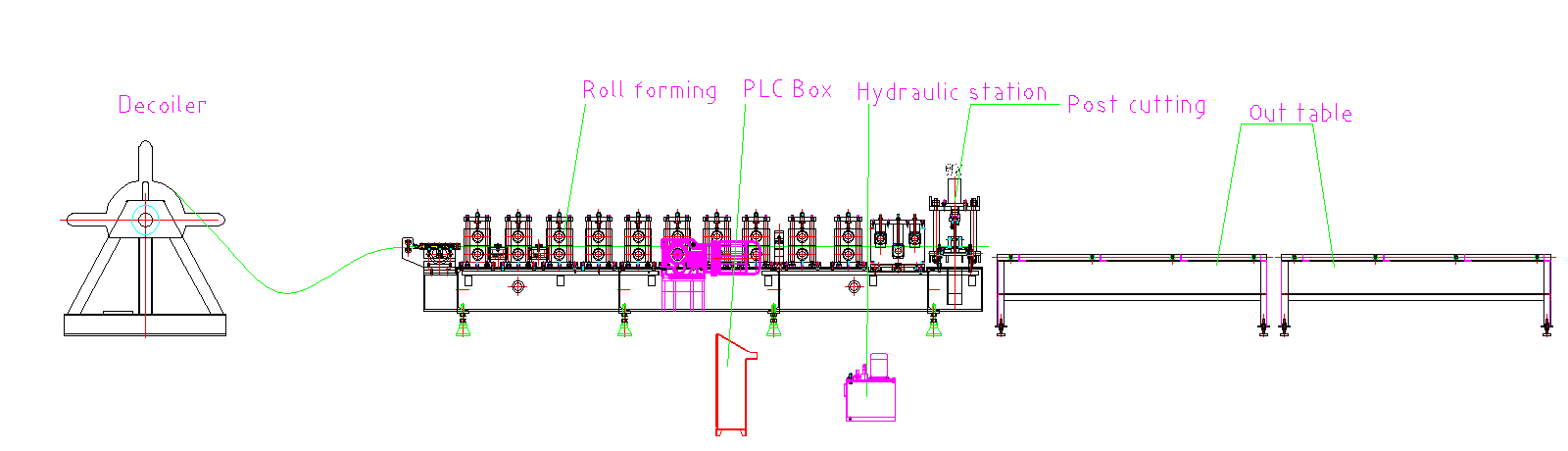

Flow Chart:

2018 High quality Door Frame Rolling Shutter Roll Forming Machine Related Video: