Good quality Standing Seam Metal Roof Machine - Z Purlin roll forming machine – Linbay Machinery

Product Detail

Description:

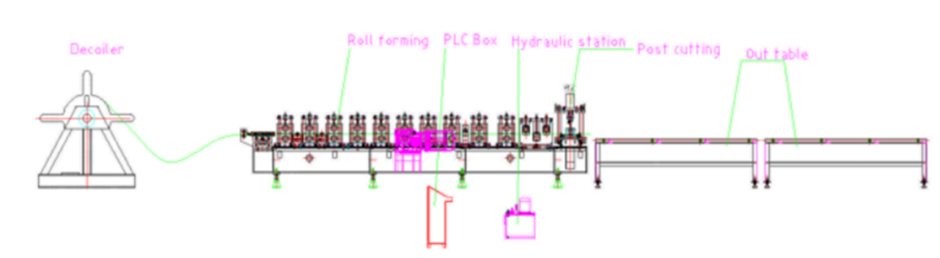

Z Purlin Roll Forming Machine can produce from 100-400mm purlin width . Normally the thickness can be formed at 1.5-3.0 mm. The lips angles can be at 45 or 90 degrees.Regarding the cutting unit ,you can choose the pre-cut or post cut.The driving system we adopt the gimbal or chain drving according to your requirement.We can design the machine as Torri Stand structure or Metal wall structure.

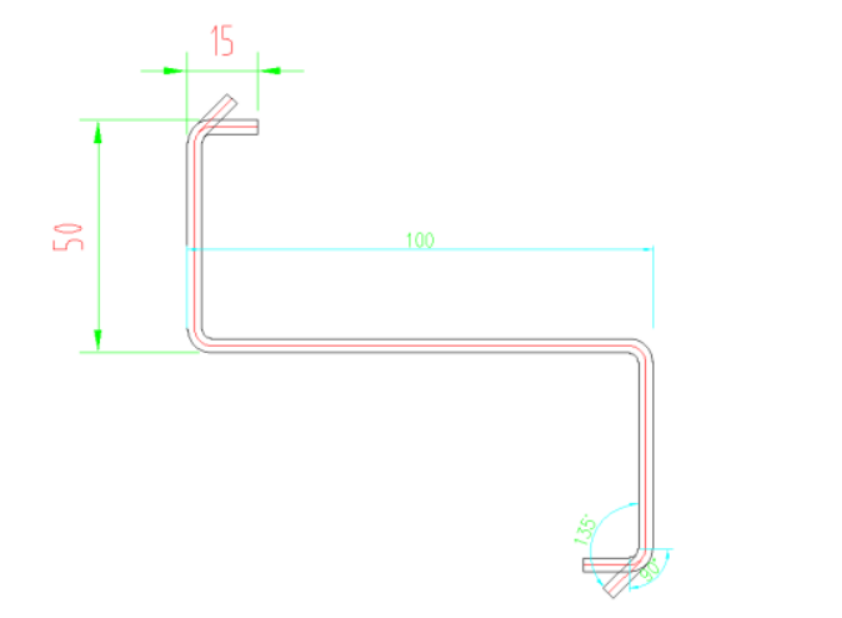

Profile:

Technical specification:

|

Z Purlin roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material | Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-3 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) | 10-25 | Or according to your requirement |

|

3 |

Forming station | 18 | According to your profile |

|

4 |

Decoiler | Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor | Sino-German Brand | Siemens |

|

6 |

PLC brand | Panasonic | Siemens |

|

7 |

Inverter brand | Yaskawa | |

|

8 |

Driving system | Chain drive | Gearbox drive |

|

9 |

Rollers’ materail | Steel #45 | GCr15 |

|

10 |

Station structure | Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system | No | Hydraulic punching station or Punching press |

|

12 |

Cutting system | Post-cutting | Pre-cutting |

|

13 |

Power supply requirement | 380V 60Hz | Or according to your requirement |

|

14 |

Machine color | Industrial blue | Or according to your requirement |

Flow Chart:

Product Tags

Good quality Standing Seam Metal Roof Machine - Z Purlin roll forming machine – Linbay Machinery Related Video: