Good User Reputation for China Wave Roof Tile Pbr Roof Panel Machine

With a full scientific excellent management process, great quality and excellent faith, we acquire very good standing and occupied this industry for Good User Reputation for China Wave Roof Tile Pbr Roof Panel Machine, Welcome to post your sample and color ring to let us produce according to your specification.Welcome your inquiry! Looking forward to building long-term cooperation with you!

With a full scientific excellent management process, great quality and excellent faith, we acquire very good standing and occupied this industry for China Wave Roof Tile Machine, conformadora de Teja toledo, maquina de Tejas metalicas, Pbr Roof Panel Machine, perfiladora de Laminas tipo teja, We would very much welcome an opportunity to do business with you and have pleasure in attaching further details of our merchandise. Excellent quality, competitive prices,punctual delivery and dependable service can be guaranteed.

Description

This Ridge Cap roll forming machine is used in roofing sheet. The normal raw material is 0.3-0.8mm thickness. Normal working speed is 10-25m/min. It has many different shapes, we can make all kinds of machine if you can offer the profile to us. We are very profesional in OEM roll forming machine.

Technical Specifications

|

Ridge cap roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.3-0.8 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

14 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

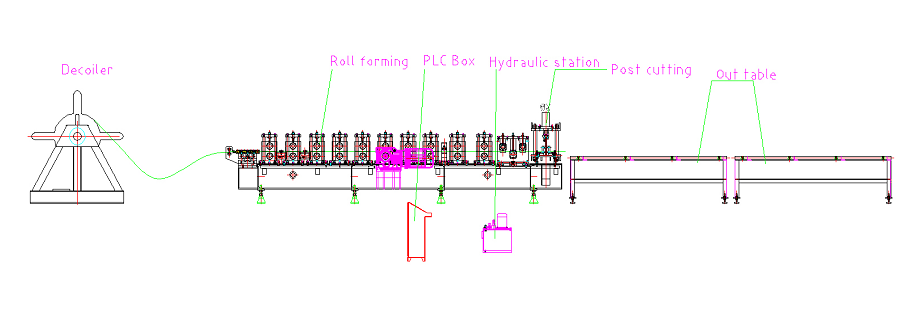

Flow Chart

Good User Reputation for China Wave Roof Tile Pbr Roof Panel Machine Related Video: