ODM Supplier China Stud & Track Roll Forming Machine for Steel Frame Building Construction

To fulfill the customers’ over-expected satisfaction , we have now our strong crew to provide our greatest general assistance which incorporates promoting, gross sales, planning, creation, top quality controlling, packing, warehousing and logistics for ODM Supplier China Stud & Track Roll Forming Machine for Steel Frame Building Construction, We have extensive goods supply and the price is our advantage. Welcome to inquire about our products.

To fulfill the customers’ over-expected satisfaction , we have now our strong crew to provide our greatest general assistance which incorporates promoting, gross sales, planning, creation, top quality controlling, packing, warehousing and logistics for angle, angle cold bending machine, angle steel, C channel roll former, China steel angle roll forming machine, China Stud & Track Roll Forming Machine, Drywall Roll Forming Machine, light gauge steel, Light Gauge Steel Roll Forming Machine, Roll Forming Machine, steel angle roll making machine, Steel Frame Building Construction, Studtrack Roll Forming Machine, With the spirit of “high quality is our company’s life; good reputation is our root”, we sincerely hope to cooperate with customers from at home and abroad and hope to build a good relationship with you.

Description:

The Stud and Track Roll Forming Machine, as known as Hat Shape Roll Forming Machine, Main Channel Roll Forming Machine, Omega Furring Channel Roll Forming Machine, Wall angle Roll Forming Machine, Ceiling Roll Forming Machine Light Steel Keel Roll Forming Machine etc. can produce studs, tracks and many other shapes derived form Shape C.

The thickness is normally can be formed at 0.25-1.2mm .

If you need to more efficiency then we recommend you adpot the Flying shear with No-stop system .

The Max. whole line speed can be reach at 40m/min.

If you want to produce more than one profile in one machine, we recomend you the double rows forming machine and triple rows forming machine to save space and economy.

Technical specification:

|

Stud, Track and Channel Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.25-1.2 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-40 | Or according to your requirement |

|

3 |

Forming station |

8-14 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

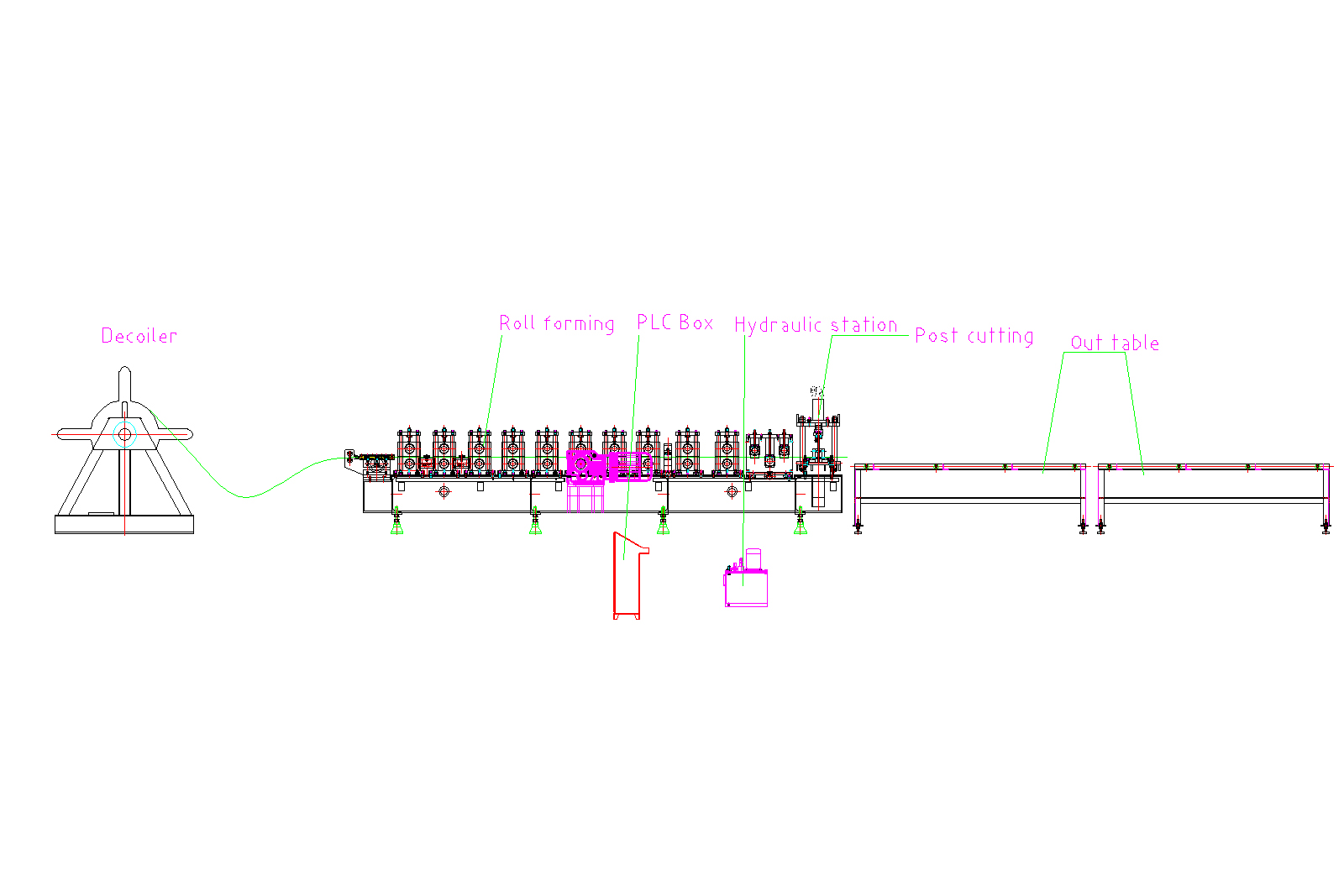

Flow Chart:

ODM Supplier China Stud & Track Roll Forming Machine for Steel Frame Building Construction Related Video: