Factory Directly supply China C Purlin Cold Roll Forming Production Line Machinery

We delight in an exceptionally good popularity amongst our customers for our fantastic product high quality, competitive cost as well as ideal service for Factory Directly supply China C Purlin Cold Roll Forming Production Line Machinery, Special emphasis to the packaging of goods to avoid any damage during transportation,Detailed attention towards the worthwhile feedback and tips of our esteemed shoppers.

We delight in an exceptionally good popularity amongst our customers for our fantastic product high quality, competitive cost as well as ideal service for Bending Machine, C Channel Roll Forming Machine, c profile roll forming machine, C purlin, C Purlin Roll Forming Machine, C Shape Roll Forming Machine, China C Purlin Machine, CZ purlin, CZS purlin, Forming Machine, Roll Forming Machine, sigma purlin, Steel C Purlin Machine, z channel forming machine, Z profile cold bending machinery, Z purlin, z purlin roll making machine, Our continual availability of high grade products and solutions in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Description:

Z Purlin Roll Forming Machine can produce from 100-400mm purlin width . Normally the thickness can be formed at 1.5-3.0 mm. The lips angles can be at 45 or 90 degrees.Regarding the cutting unit ,you can choose the pre-cut or post cut.The driving system we adopt the gimbal or chain drving according to your requirement.We can design the machine as Torri Stand structure or Metal wall structure.

Technical specification:

|

Z Purlin roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material | Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-3 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) | 10-25 | Or according to your requirement |

|

3 |

Forming station | 18 | According to your profile |

|

4 |

Decoiler | Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor | Sino-German Brand | Siemens |

|

6 |

PLC brand | Panasonic | Siemens |

|

7 |

Inverter brand | Yaskawa | |

|

8 |

Driving system | Chain drive | Gearbox drive |

|

9 |

Rollers’ materail | Steel #45 | GCr15 |

|

10 |

Station structure | Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system | No | Hydraulic punching station or Punching press |

|

12 |

Cutting system | Post-cutting | Pre-cutting |

|

13 |

Power supply requirement | 380V 60Hz | Or according to your requirement |

|

14 |

Machine color | Industrial blue | Or according to your requirement |

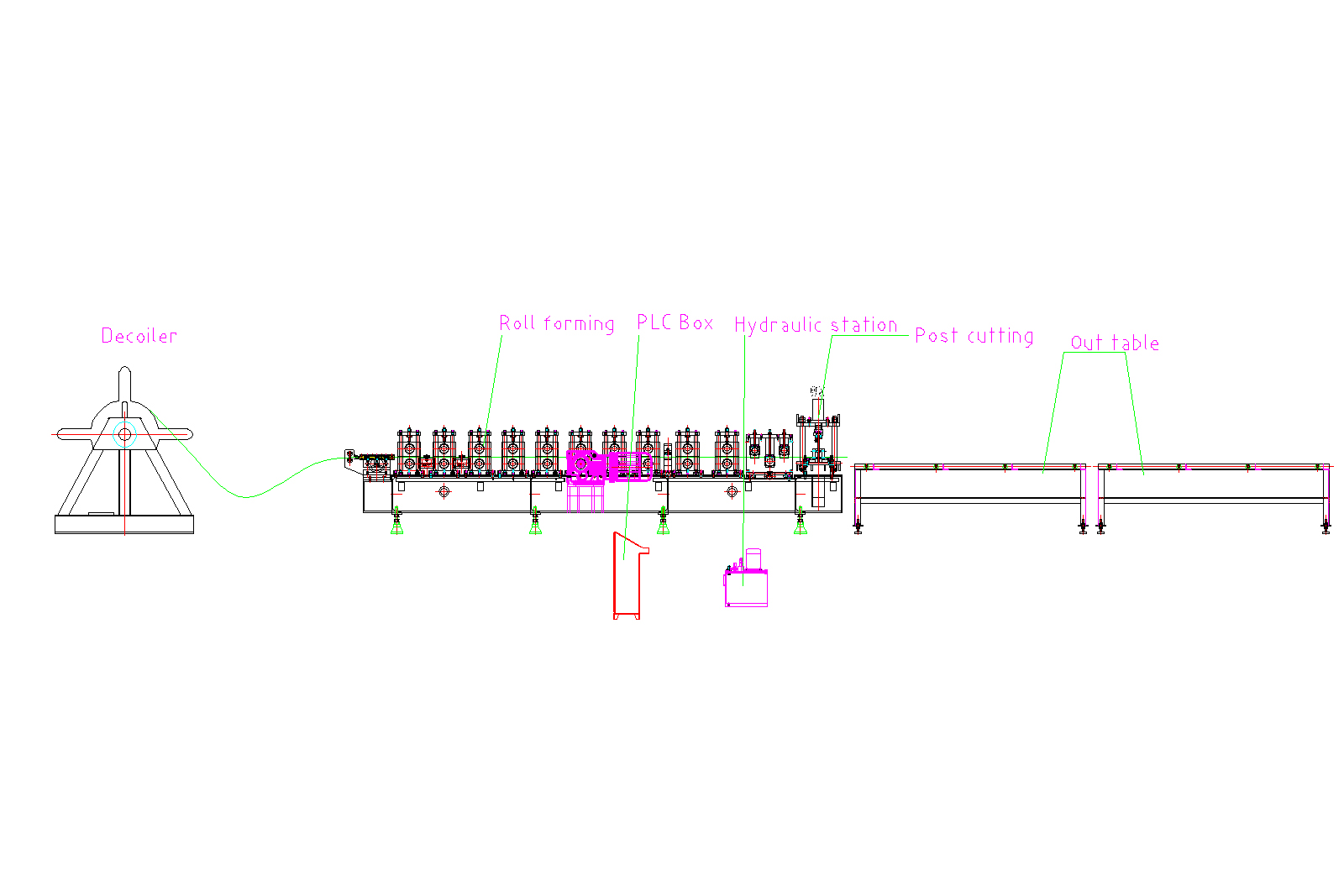

Flow Chart:

Factory Directly supply China C Purlin Cold Roll Forming Production Line Machinery Related Video: