Factory Price Door Frame Bending Machine - Double Layer Panel roll forming machine – Linbay Machinery

Description:

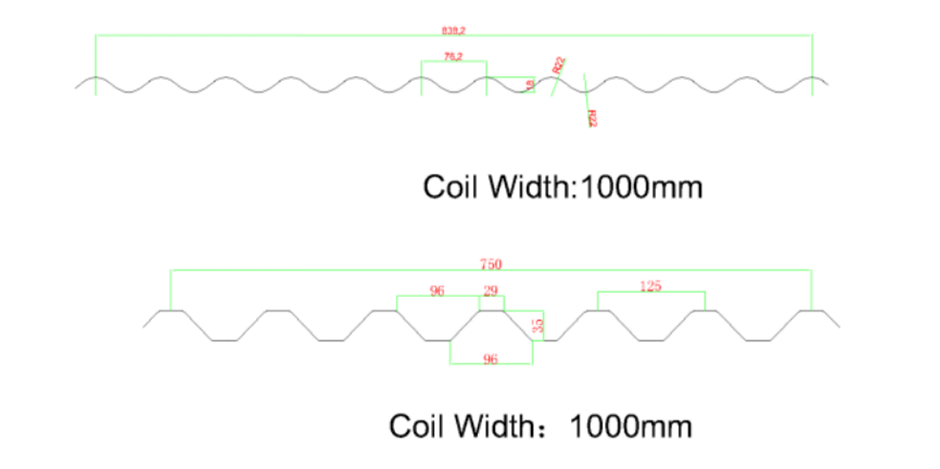

Double Layer Roll Forming Machine can produce two different profile drawings in one machine, it can save more room and of course more economy compared with two different machines.

You can choose two different kind of profile drawings as well as corrugated sheet drawing, but one time only can produce one layer profile . There is one clutch as one side of the machine, and we just need simply to move one handle wheel to make other layer profile.

Profile:

Technical specification:

|

Double Layer Corrugated sheet roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.3-0.8 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

20-23 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

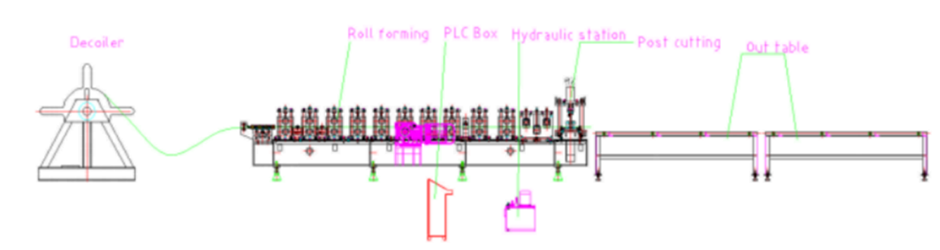

Flow Chart:

Factory Price Door Frame Bending Machine - Double Layer Panel roll forming machine – Linbay Machinery Related Video: