Flying punching and cutting stud roll forming machine

Perfil

These steel stud wall products are utilized in various applications, such as load-bearing walls, curtain walls, floor joists, and roof trusses.

Studs, tracks, omegas, and other light gauge profiles are typically produced by cold roll forming lines. The profile dimensions and punching patterns can be customized.

Real case-Flow chart

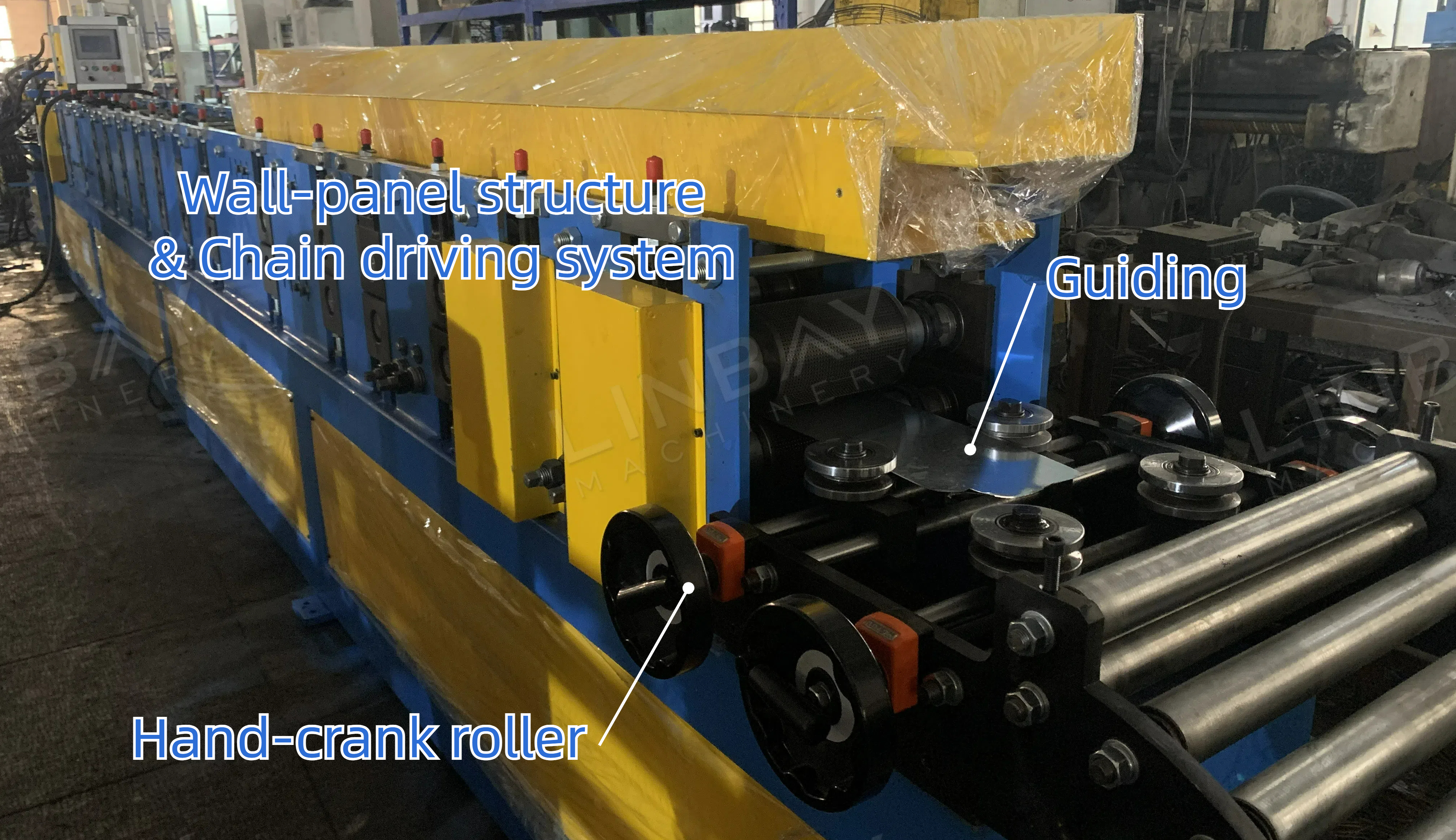

Decoiler–Guiding–Roll former–Flying hydraulic punch–Flying hydraulic cut–Out table

Real case-Main Technical Parameters

1.Line speed: 0-15m/min with perforation, adjustable

2.Forming speed: 0-40m/min

3.Suitable material:Galvanized steel

4.Material thickness: 0.4-0.8mm

5.Roll forming machine: Wall panel structure

6.Driving system: Chain driving system

7.Punching and cutting system: Hydraulic power. Flying type, roll former doesn’t stop when cutting.

8.PLC cabinet: Siemens system. Portable type.

Real case-Machinery

1.Decoiler*1

2.Roll forming machine*1

3.Flying hydraulic punch machine*1

4.Flying cutting machine*1

5.Out table*2

6.PLC control cabinet*1

7.Hydraulic station*1

8.Spare parts box(Free)*1

Container size: 1x20GP

Real case-Description

Manual Decoiler

● Due to the thinness of stud profiles 0.4-0.8mm, a manual decoiler can meet the uncoiling needs.

● Inefficient: However, it lacks its own power and relies on the roll forming machine to pull the steel coil.

● Requires manual assistance: The mandrel tensioning is also done manually, resulting in lower efficiency and only fulfilling basic uncoiling requirements.

Optional Decoiler Type: Motorized Decoiler

● Powered by a motor, it increases uncoiling efficiency and reduces the need for manual intervention and labor costs.

Optional decoiler: Hydraulic decoiler

● Stable and robust frame: Used for loading steel coils. The hydraulic-powered decoiler ensures a more efficient and safe feeding process into the production line.

● Core expansion device: Hydraulic-driven mandrel or arbor expands and contracts to fit steel coils with inner diameters of 490-510mm (or customized), securing the coils for smooth uncoiling.

● Press-arm: The hydraulic press-arm holds the coil in place, preventing sudden release of internal stress that could harm workers.

● Coil retainer: Firmly attached to the mandrel blades with screws and nuts, it prevents the coil from slipping off the shaft. It can be easily installed and removed.

● Control system: Equipped with a PLC and control panel, featuring an emergency stop button for enhanced safety.

Guiding

● Primary function: To guide the steel coil along the machine’s centerline, preventing misalignment that may cause twisting, bending, burrs, and dimensional issues in the finished product.

● Guiding devices: Multiple guiding rollers are located at the entrance and within the roll forming machine to enhance the guiding effect.

● Maintenance: Regularly calibrate the distance of the guiding devices, especially after transport and during long-term use.

● Pre-shipment: We, Linbay team measures and records the guiding width in the user manual for client calibration upon receipt.

● The guiding width can be finely adjusted using the hand-crank roller.

Roll forming machine

● Multiple dimensions are available: This production line can manually adjust the forming points on the rollers to produce three different sizes of studs. We provide manuals, commissioning videos, video calls, and on-site guidance from engineers to help customers’ workers learn how to change the rollers.

Click the picture below to see how to change the roller space:

● Asymmetrical profile: Unlike conventional stud profiles, this Montante construcción en seco profile features two asymmetrical high edges, requiring more precise design of the forming machine rollers.

● Economical and suitable configuration: Features a wall-panel structure and chain driving system, which is quite suitable when the steel coil is 0.4-0.8mm thick.

● Embossing rollers: The steel coil passes through a set of embossing rollers, imprinting dot patterns on the profile surface to increase friction and enhance cement adhesion.

● Chain cover: The chains are covered by a metal box, ensuring worker safety and protecting the chains from damage caused by airborne particles.

● Rollers: Chrome-plated and heat-treated for rust and corrosion resistance, extending their lifespan.

● Main motor: Standard 380V, 50Hz, 3Ph, with customization available.

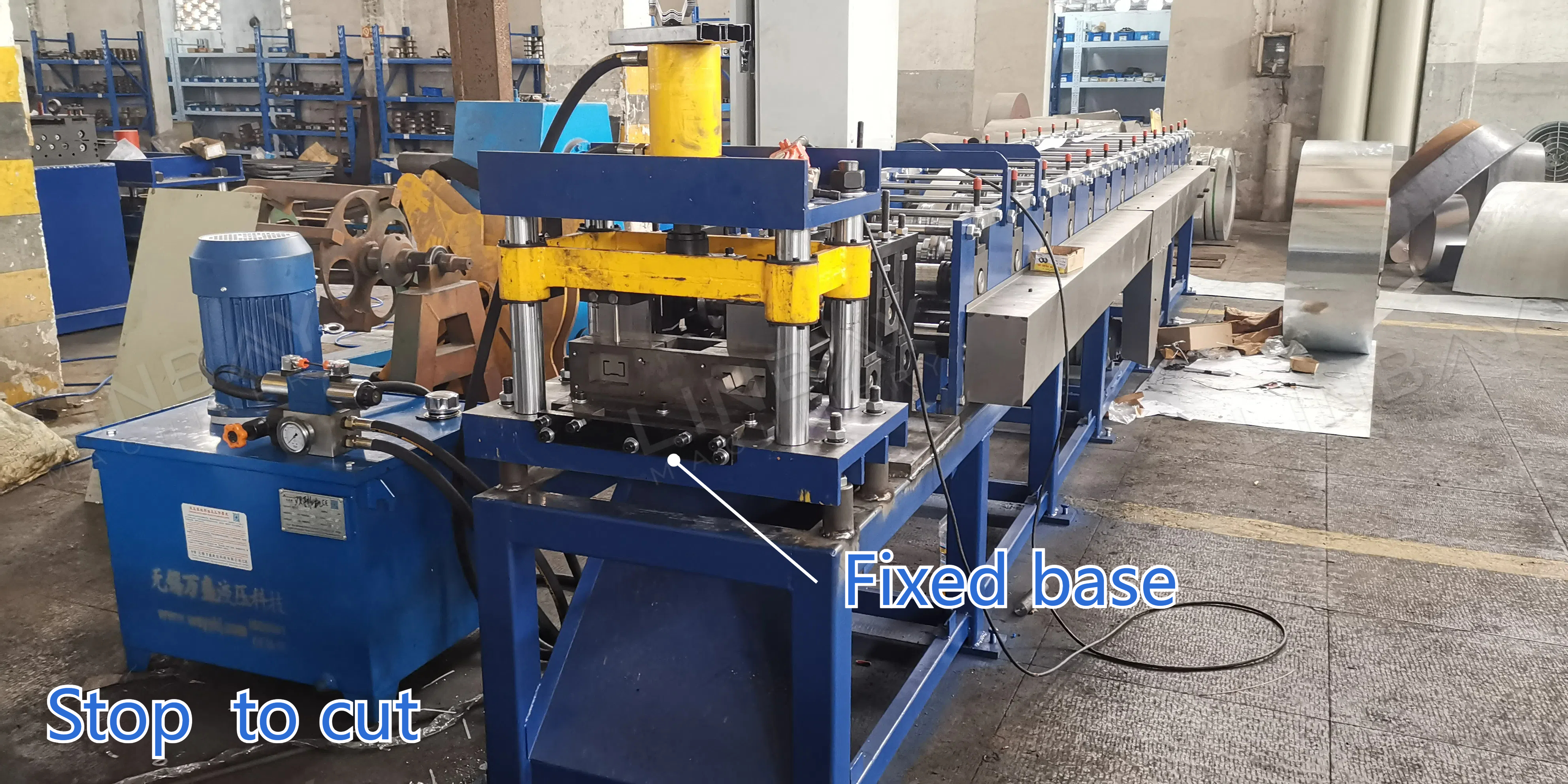

Flying hydraulic punch & Flying hydraulic cut

● Higher efficiency: The punching and cutting machines share a single base, allowing them to move forward at the same speed as the forming machine. This keeps the punching and cutting areas relatively stationary, enabling continuous operation of the forming machine and ultimately improving overall production efficiency.

● Two-station design: Punching and cutting are performed in two separate hydraulic stations, offering greater flexibility. Punching molds can be customized according to customer drawings.

● High cutting length accuracy: Tolerance within ±1mm, achieved using an encoder to measure the steel coil’s advance length, converting it to electrical signals, and feeding this data back to the PLC cabinet. Workers can set the cutting length, production quantity, and speed on the PLC screen.

Optional Cost-Effective Solution: Stop-Punching and Stop-Cutting

For lower production demands and limited budgets, stop-punching and stop-cutting configurations can be used. During punching and cutting, the forming machine must pause to accommodate these processes. While this results in lower efficiency, the quality of punching and cutting remains high.

Flying punching and cutting stud roll forming machine Related Video: