High Quality Metal Stud and Track Roll Forming Machine China Production Line

We insist on offering good quality generation with very good business enterprise concept, honest income as well as best and fast assistance. it will bring you not only the premium quality product or service and huge profit, but probably the most significant is usually to occupy the endless market for High Quality Metal Stud and Track Roll Forming Machine China Production Line, We sincerely welcome buyers from both at your house and overseas to arrive to barter organization with us.

We insist on offering good quality generation with very good business enterprise concept, honest income as well as best and fast assistance. it will bring you not only the premium quality product or service and huge profit, but probably the most significant is usually to occupy the endless market for angle, angle cold bending machine, angle steel, C channel roll former, ceiling panel forming machinery, China steel angle roll forming machine, China Stud and Track Roll Forming Machine, Drywall Roll Forming Machine, light gauge steel, light gauge steel machine, Light Gauge Steel Roll Forming Machine, Metal Stud Roll Forming Machine, Omega roll bending machine, Roll Forming Machine, steel angle making machinery, steel angle roll making machine, stud&track, Studtrack Roll Forming Machine, top hat, top hat roll forming machine manufacturer, We are going to do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

Description

The Stud and Track Roll Forming Machine, as known as Hat Shape Roll Forming Machine, Main Channel Roll Forming Machine, Omega Furring Channel Roll Forming Machine, Wall angle Roll Forming Machine, Ceiling Roll Forming Machine Light Steel Keel Roll Forming Machine etc. can produce studs, tracks and many other shapes derived form Shape C.

The thickness is normally can be formed at 0.25-1.2mm .

If you need to more efficiency then we recommend you adpot the Flying shear with No-stop system .

The Max. whole line speed can be reach at 40m/min.

If you want to produce more than one profile in one machine, we recomend you the double rows forming machine and triple rows forming machine to save space and economy.

Technical Specifications

|

Stud, Track and Channel Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.25-1.2 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-40 | Or according to your requirement |

|

3 |

Forming station |

8-14 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

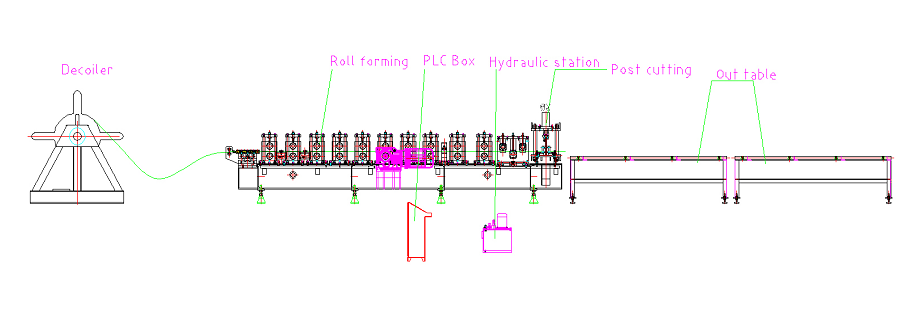

Flow Chart

High Quality Metal Stud and Track Roll Forming Machine China Production Line Related Video: