Online Exporter Latest CZ Purlin Steel Profiled Interchangeable Roll Forming Machine

The organization upholds the philosophy of “Be No.1 in good quality, be rooted on credit history and trustworthiness for growth”, will keep on to provide previous and new customers from home and overseas whole-heatedly for Online Exporter Latest CZ Purlin Steel Profiled Interchangeable Roll Forming Machine, We believe that this sets us apart from the competition and makes shoppers choose and trust us. We all wish to make win-win deals with our buyers, so give us a contact today and create a new pal!

The organization upholds the philosophy of “Be No.1 in good quality, be rooted on credit history and trustworthiness for growth”, will keep on to provide previous and new customers from home and overseas whole-heatedly for c&z purlin forming machine, Cold Roll Forming Machine, cz purlin machine, cz purlin machinery, cz purlin machines, Cz Purlin Roll Forming Machine, cz purlin roll forming machinery, cz purlin roll forming machines, Purlin Forming Machine, purlin roll former, Roll Forming Machine, Our monthly output is more than 5000pcs. We have set up a strict quality control system. Please feel free to contact us for further information. We hope that we can establish long-term business relationships with you and carry out business on a mutually beneficial basis. We are and will be always trying our best to serve you.

Description:

This C/Z Quick Interchangeable Roll Forming Machine adopts a special structure. The rollers for C&Z are changed very quickly without dismantle any parts . One machine can produce all specifications of C/Z/U purlins . Crimples are optional to increase rigidity of purlins. The width of the purlins can be automatically adjusted by PLC. If you need more economy then can be Handle Wheel adjusting as well. This machine we adopt Pre-cutting system.

Technical specification:

|

C/Z/U Quick Interchangeable Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-3 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

20 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Pre-cutting | Post- universal cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

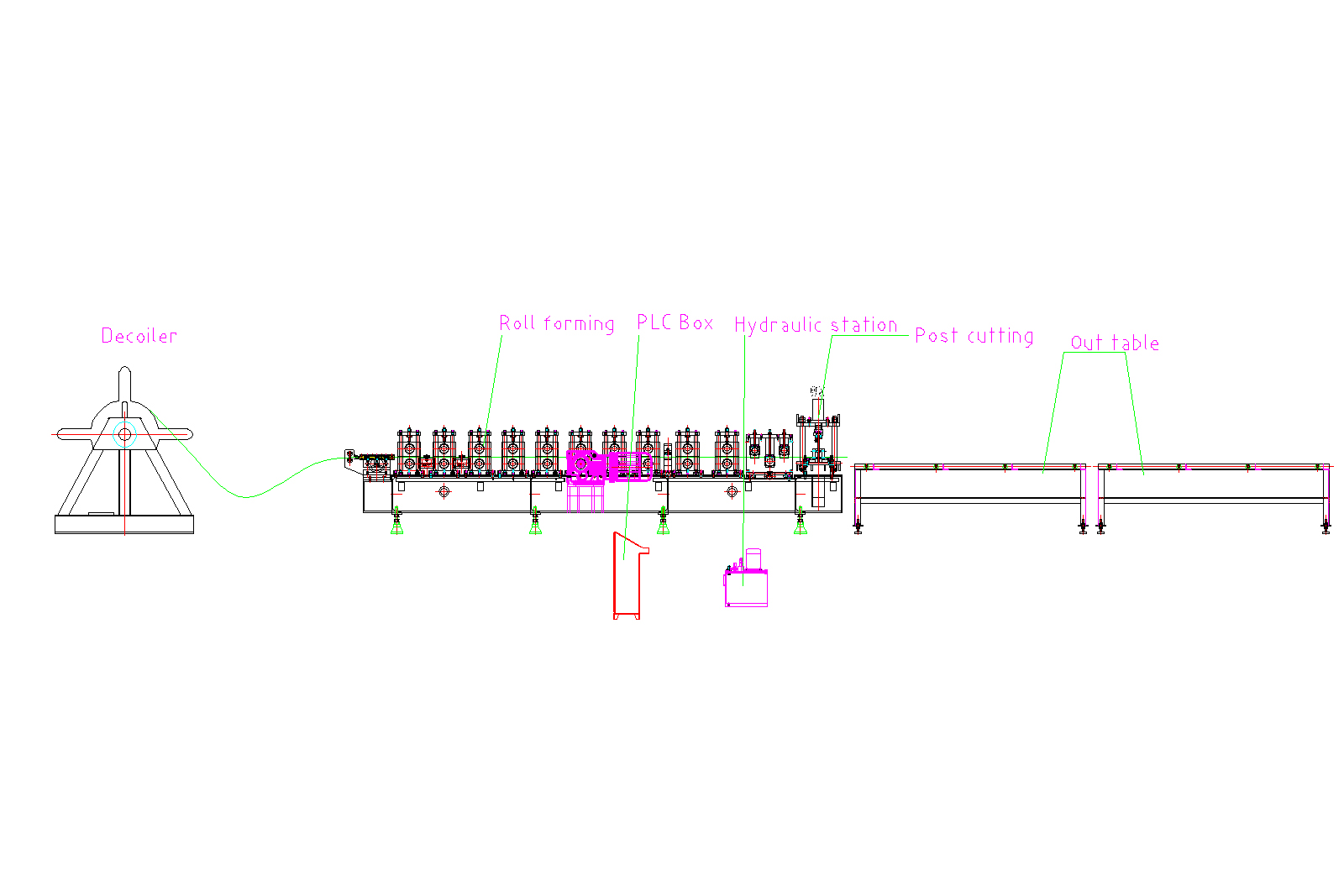

Flow Chart:

Online Exporter Latest CZ Purlin Steel Profiled Interchangeable Roll Forming Machine Related Video: