Quots for China 10-30m/Min PLC Control Storage Rack Shelf Roll Forming Machine

Generally customer-oriented, and it’s our ultimate goal for being not only the most trusted, trustable and honest provider, but also the partner for our customers for Quots for China 10-30m/Min PLC Control Storage Rack Shelf Roll Forming Machine, Welcome your visiting and any your inquires,sincerely hope we can have chance to cooperate with you and we can build up long well business relationship with you.

Generally customer-oriented, and it’s our ultimate goal for being not only the most trusted, trustable and honest provider, but also the partner for our customers for box beam, bracing roll forming machine, China Storage Rack Roll Forming Machine, cold bending machinery, Steel Roll Forming Machine, step beam, step beam roll former, Storage Rack Roll Forming, warehouse shelf panel forming machine, warehouse shelf roll making machine, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

Description

Goods Shelf Roll Forming Machine including Shelf Roll Forming Machine, Pallet Rack Roll Forming Machine.Pallet rack can both store multi-veriety goods with small quantity and also unified goods with big quantity. Normally thickness can be formed at 2.5mm and the speed is about 20-30m/min.This machine is widely used in high warehouses.

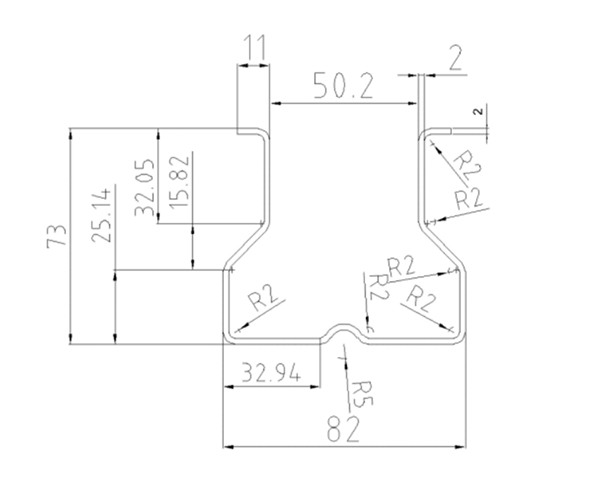

Profile

Technical Specifications

|

Warehouse Pallet Rack/Goods Shelf Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-2.5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

20 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron stationOr Wall panel station |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

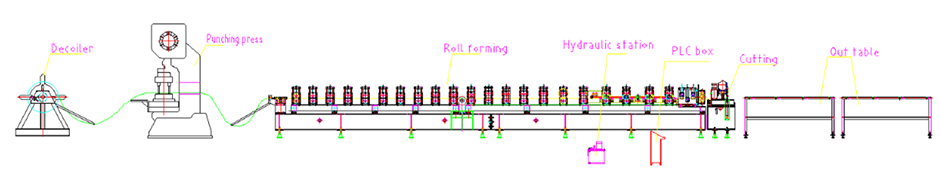

Flow Chart

Quots for China 10-30m/Min PLC Control Storage Rack Shelf Roll Forming Machine Related Video: